Solebox x New Balance 1500 "Nazar Eye" Interview

Few have been as fortunate and furious on the collaboration front as German sneaker boutique

Few have been as fortunate and furious on the collaboration front as German sneaker boutique Solebox. Teaming up with many of the industry’s heavyweights, one of their greatest collaborative projects resulted in the Purple Devil pack with New Balance which has still garnered much talk despite releasing a few years ago. And while Solebox has worked together with many other footwear labels, there seems to be an inherent softspot for New Balance which can be seen between the two’s solid track record. For the whole of the lifestyle footwear world, no particular brand still maintains such a strong focus and dedication to quality of production as the classic NB, and for those even just a little bit versed in sneaker culture, many will immediately associate the word “Flimby” with top of the line execution. While New Balance doesn’t exactly use Flimby as marketing fooder, the factory name in itself is very much a subdued marketing point. But then again New Balance’s results speak for themselves. As Hikmet and company of Solebox prepare for their Saturday, November 22nd launch of their latest New Balance, the 1500 “Nazar Eye”, we had a chance to ask the man of collaborations as well as New Balance Flimby Factory employee Dan Newton some questions regarding their the shoe and the factory.

Dan Newton of New Balance Flimby

How many shoes a year do you produce

Our Flimby factory produces around 1.3M pairs of shoes every year, each one carrying the ‘Made in England’ signature. This includes everything from our most technical running product to fitness running styles, trail and outdoor models and also our inline range of lifestyle products. This particular run of 1500s will be produced as CTB – Cut To Box – essentially this means that the whole shoe is cut, stitched and assembled in the UK. This is the same for most of the lifestyle shoes we produce here – around 3,500 pairs per week or 150,000 pairs per year. This is our ‘Jewel in the Crown’ in terms of manufacturing and allows us to make some very special hand crafted, artisan product in low quantities. The majority of the performance line is produced as SU – Sourced Upper – which means the upper is cut and stitched outside the UK but is then brought in with the sole for assembly in Flimby enabling us to deliver higher degrees of quality in the finished articles.

What’s the average time it takes to produce one pair of shoes from start to finish?

It normally takes around 2 hours to make a pair of CTB shoes from start to finish. This includes the time taken to cut out all the parts, stitch them together and finally attach the sole. If the shoe uses new or different materials than the factory is used to then this time can become longer.

How important is it to maintain a factory in the United Kingdom as other people look for other cheaper alternatives?

It is extremely important for us to still produce in the UK. Our build quality, attention to detail and speed to market are just some of the factors that other brands cannot offer their customers or consumers. Domestic manufacturing, in a consumer market, has always been at the heart of the New Balance brand, whether at home here in the UK or in the US with the 5 factories they have there. With lean manufacturing methods it is still possible to produce a sourced upper product at a similar price to that of imported styles. Manufacturing here means that we are able to tap into over 200 years of experience from the UKs shoe making industry. We have a highly skilled, committed and driven workforce with many operatives that have worked at Flimby since it opened 26 years ago. In times of global economic instability we’re in good shape having the ability to produce in a number of locations globally.

What does Flimby represent to New Balance and its brand identity?

Flimby represents a huge part of the New Balance identity, whether it’s the brands commitment to domestic manufacturing, our commitment to our work force or the commitment to the products we make, they all have a sense of pride. No other sports brand can lay claim to UK manufacturing at this level. We not only have the ability to create special projects such as Solebox’s 1500, but also highly technical products rich in our brands heritage as a running shoe company. I’ve worked at New Balance for 4 years, and in that time I’ve got to know the team at Flimby very well, you can tell that they are very proud of their shoes, passionate about what they do, they have a great sense of humour, but they are also hard workers. In that respect I think that it’s probably the people that make Flimby what it is, and that passion and pride directly translates into our brand identity.

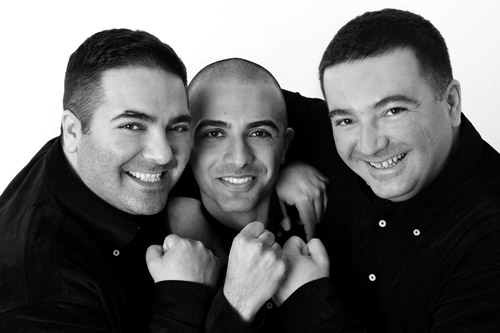

Hikmet Sugoer of Solebox

Photo: Claudia Cassagranda

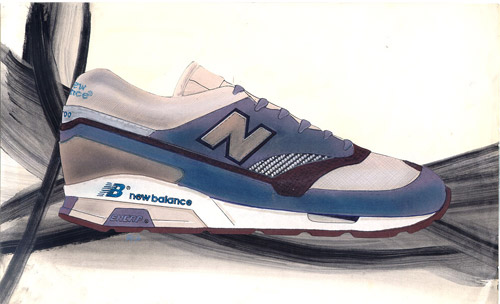

What is the concept behind this design?

The main concept is the “Nazar Eye” aka “Evil Eye”. It is not only based in Turkish culture, but you see it through many religions and cultures. It was a good theme to match up with the shoes. How often you see people looking, that envy your shoes. This time you have a built in protection against envy and evil people with the “Evil Eye” ornament! The rest of the shoe stays pretty classic and simple. The main actor are here the materials. Premium suede combined with mesh, nubuck and 3M… that’s it. New Balance stands for quality not really for bright colors. And we love the 1500s, which are by the way not available anymore in the inline collection.

With some many consistent collaborations, do you see yourself running out of ideas?

NO! If you see what is coming in 2009 you will see that our collaborations are always having something special. Sounds stupid to say this, but this is not business for us, it is fun! We are enjoying our passion we have and we have had good luck that the companies, and we’re sharing it amongst all of us. Our aim is to satisfy you guys out there. It is like a party where we are the DJs. We like to play the good music. Not always possible but we try to do our best.

Can you give a little background regarding the shoe’s history within the New Balance family?

The 1500 is a really, really strong and aggressive silhouette. The most interesting and honorable story for me: The original Designer of the 1500s contacted me, Steven Smith. This is what he told me regarding the history of the 1500s:

It was meant to be a series of the best of the best of what NB had to offer. There was a 1300, then a 1400 and the 1500 was the running update that was to be the best running shoe we had ever made. When the 1500 became a series it was expanded to a tennis model and a basketball model. The shape was a sophisticated redefinition of what the 1400 represented. It also set the direction for what the models below would look like. The main pattern features were the NB flextended saddle a forefoot support/swaybar of mesh and a lockdown underlay at the top of the collar. We aslo chose to use a pigskin lining and a plush collar foam. One of the coolest parts of the shoe was the complex 5 part midsole tool that we developed through New Balance Japan with Shohei Karata of NB Japan.

Big Thank You to Steven Smith to creating one of my favorite all time classics out there.

What’s the best part about doing a collaboration?

To see your first sample. It is a really great feeling to open the box or package to see your work! And to see then your shoes in different countries is the next great thing. Thank you to all companies who are working with us together!

A big thank you to the New Balance UK Team: Dan, Richard, Mike, Robert and of course Lucy for packing the shoes so carefully!